A double lock stitch is a technique often seen in industrial settings, where two needles and two bobbins work together to create two parallel rows of lockstitches.

Also called a double needle lock stitch sewing machine. This method is prized for its exceptional strength and durability. That’s why it is perfect for heavy-duty garments like jeans, jackets, and workwear.

The moment I hear it, I sit with my sewing machine and start stitching. So,

Double Lock Stitch

To make a double lock stitch, use a sewing machine with two needles and two bobbins, aligning them to sew parallel rows of lockstitches in one pass.

It looks stronger than regular lockstitch, or is it? Let’s find it.

Table of Contents

What Is A Double Lock Stitch?

A double lock stitch is a sewing technique that involves sewing two parallel rows of lock stitches, which are formed by interlocking the needle thread and bobbin thread tightly. That’s why it’s called a double needle lock stitch sewing machine.

Unlike a single lock stitch, the double lock stitch provides added security against seam unraveling. It ensures your project stays strong and long-lasting like other double stitches.

What Is A Double Lock Stitch Sewing Machine?

A double lock stitch sewing machine is a specialized type of sewing machine designed to create double rows of lock stitches smoothly. Unlike a standard lock stitch machine, which forms a single row of interlocked stitches.

It is combining the needle thread and the bobbin thread. The double lock stitch machine produces two parallel rows of these strong, secure stitches in one pass.

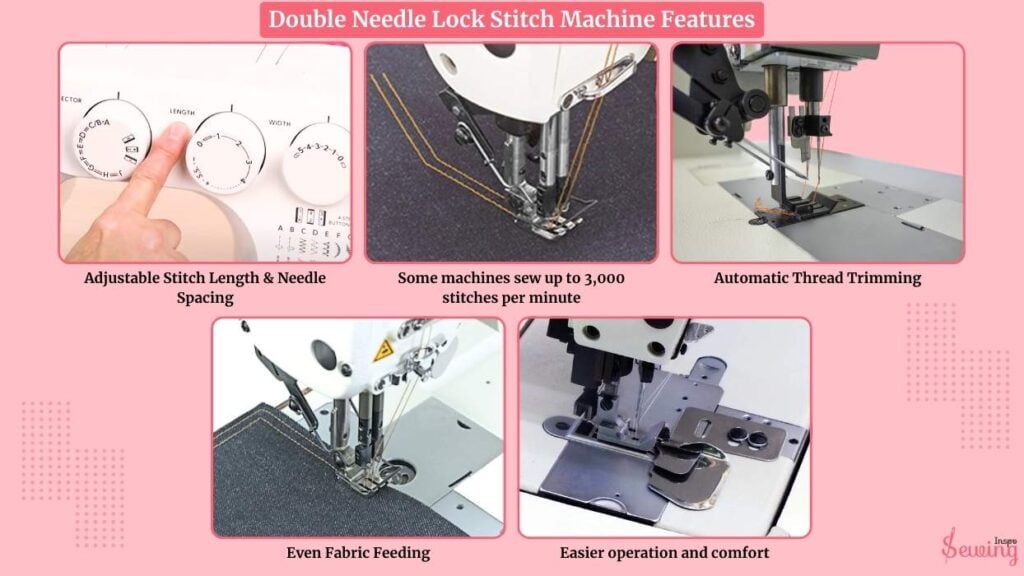

Double Needle Lock Stitch Machine Features

As you can tell, this machine is different from your regular machine. So it, of course, has some different features.

The most noticeable feature of a double lock stitch sewing machine is that it comes with 2 needles sewing side by side. It saves time compared to single-needle machines. like double top stitch sewing machine.

Another noticeable feature includes:

- Adjustable Stitch Length & Needle Spacing

- Some machines sew up to 3,000 stitches per minute.

- Automatic Thread Trimming

- Even Fabric Feeding

- Easier operation and comfort.

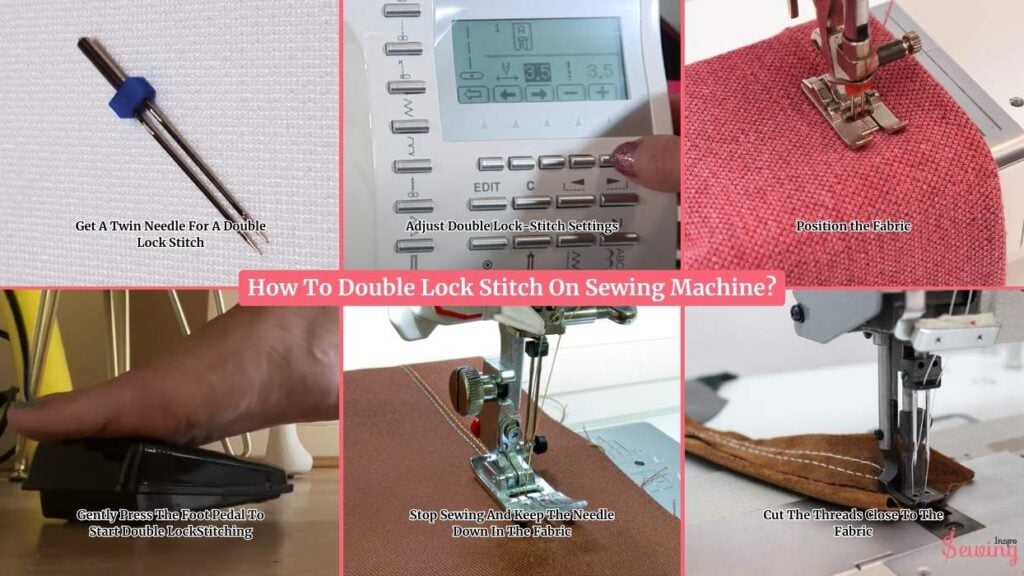

How To Double Lock Stitch On Sewing Machine?

To do a double lock stitch on a sewing machine, follow the steps below,

Get A Twin Needle For A Double Lock Stitch

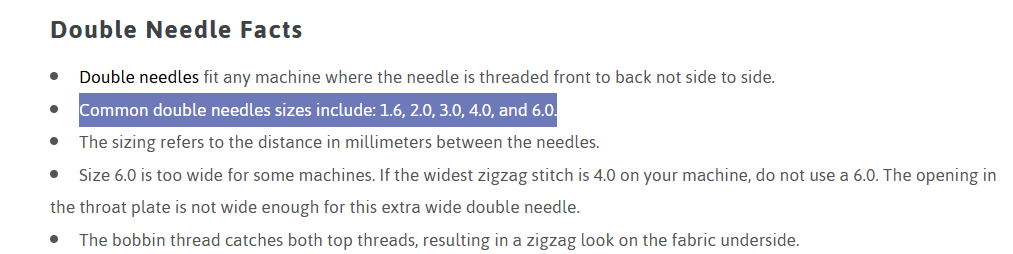

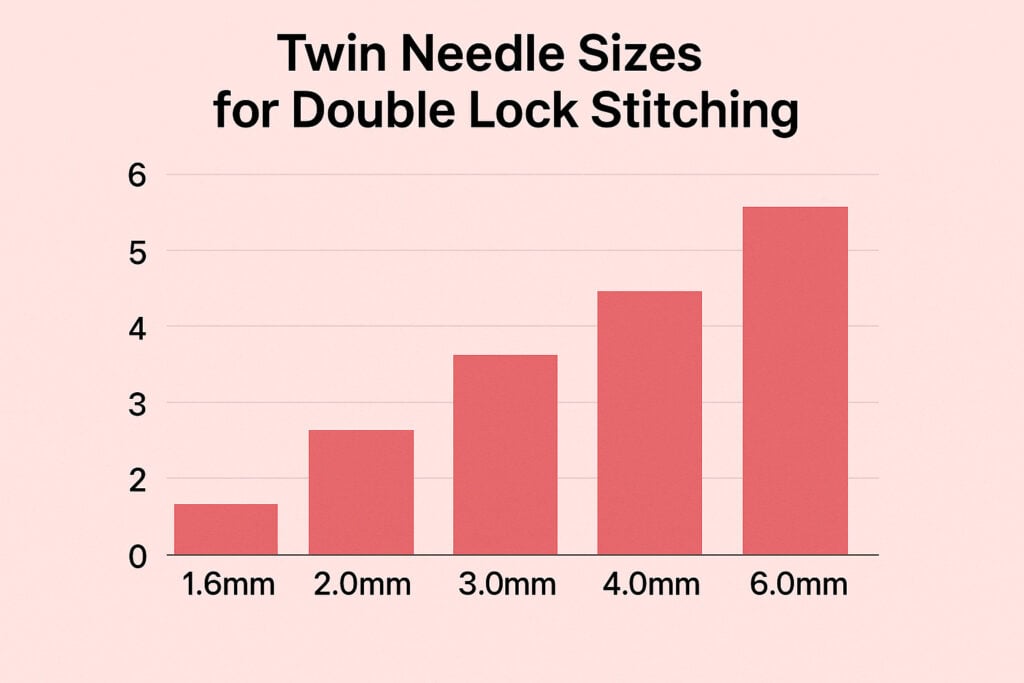

Twin needles for double lock stitching come in different sizes, usually measured by the distance between the two needles in millimeters, like 1.6mm, 2.0mm, 3.0mm, or 4.0mm.

The size you pick depends on how wide you want your stitch and what your sewing machine can handle.

For double lockstitch, I often go with a 2.5mm or 3.0mm twin needle. If I’m working with heavier fabrics like denim, I might choose a wider twin needle 4.0mm or even 6.0m. However, I always ensure that my machine can handle that width first.

Adjust Double Lock-Stitch Settings

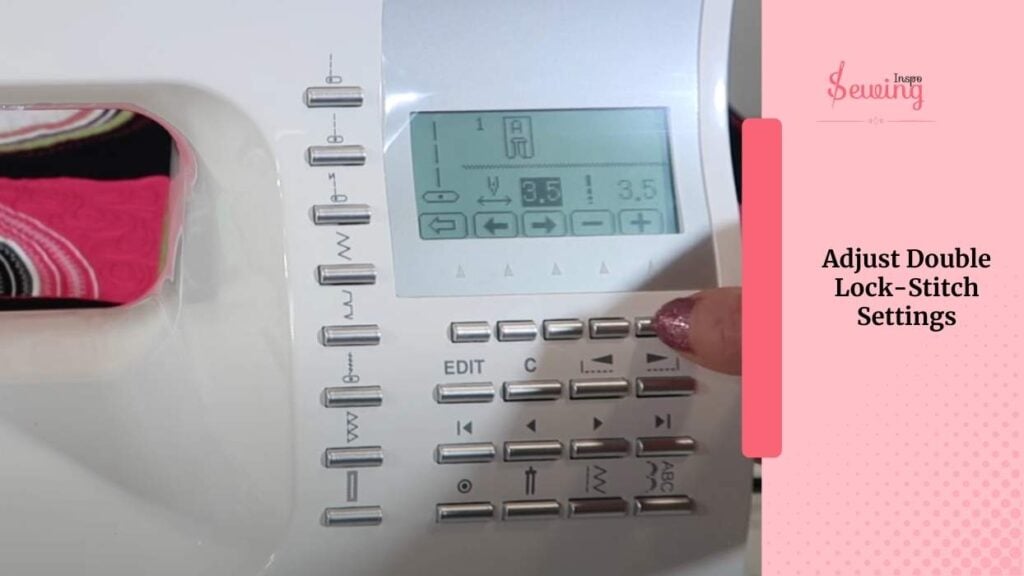

Then, I switch my machine’s stitch to a straight stitch since the double needle already creates two parallel lines. The stitch width should be set to 0 because the needle spacing controls the distance between the two stitch lines.

For stitch length,

I select somewhere between 2.5 mm to 3 mm for a double lockstitch. This length provides a sturdy stitch that holds well without bunching the fabric or jump stitching issue.

If my machine lets me, I also adjust the thread tension slightly to balance the two threads and get an even stitch on both sides of the fabric, like double chainstitch.

Position the Fabric

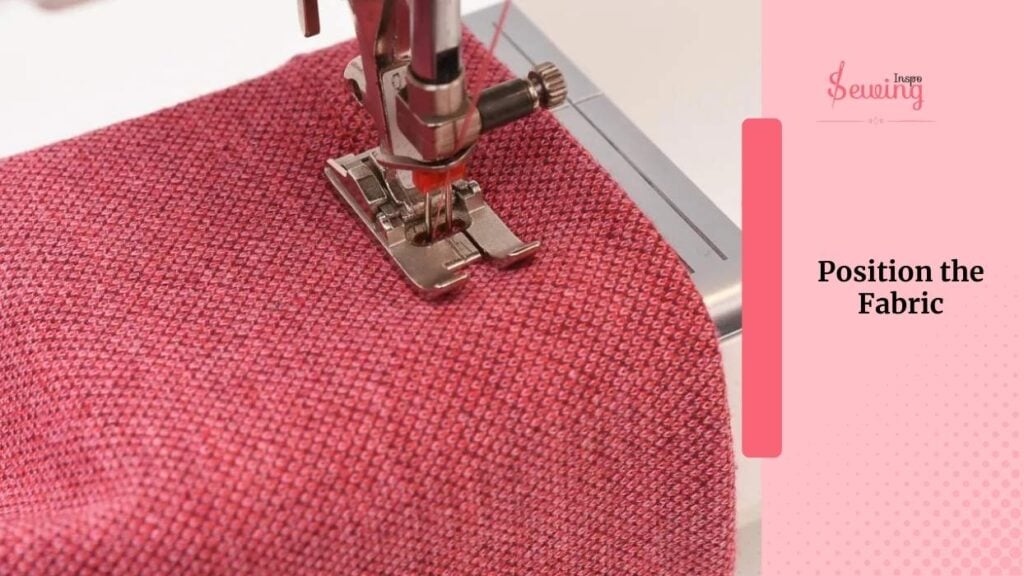

Position my fabric carefully under the presser foot, lining up the edge or seam where I want the double lock stitch to start.

I lower the presser foot to hold the fabric firmly but without stretching it. If I’m sewing something thick or bulky, I make sure the fabric lies flat and smooth to avoid puckering. Taking a moment here helps keep my stitches even and straight throughout.

Gently Press The Foot Pedal To Start Double LockStitching

I gently press the foot pedal to start stitching, moving slowly at first. I guide the fabric steadily with both hands. Ensure it remains aligned straight under the needle.

Because the double needle sews two rows simultaneously, like a double overlock stitch,

I watch closely to ensure the fabric feeds evenly and the stitches form properly. If I notice any bunching or uneven stitching. I stop and adjust the fabric or tension before continuing.

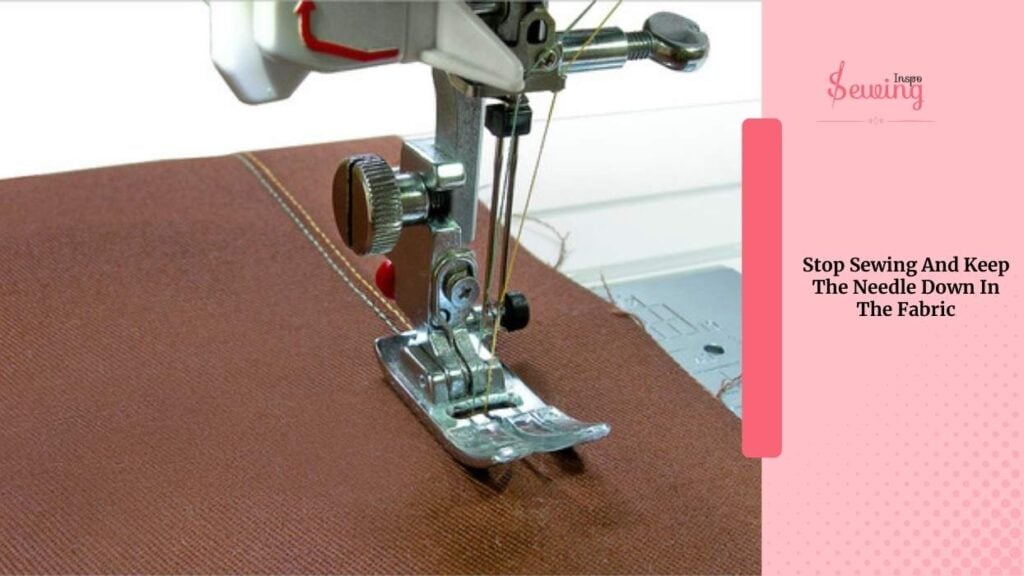

Stop Sewing And Keep The Needle Down In The Fabric.

Once I reach the end of the seam, I stop sewing and keep the needle down in the fabric. I raise the presser foot and carefully pivot if needed.

To lock the stitches and prevent unraveling,

I backstitch by reversing the machine a few stitches. This “double locks” the seam, giving it extra strength.

After backstitching, I bring the needle up, lift the presser foot, and pull the fabric away gently.

Cut The Threads Close To The Fabric

I cut the threads close to the fabric without damaging the stitches. I check the seam to make sure both parallel stitch lines are even, neat, and secure.

The double lock stitch appears professional and offers added durability. It is perfect for garments, upholstery, or any project needing strong seams.

Double Needle Lockstitch Machine PDF

Frequently Asked Questions

What fabrics work best for double lock stitching?

Double lock stitch works well on medium to heavy fabrics like denim, canvas, and upholstery materials, providing strong, durable seams.

Can I use any twin needle for double lock stitching?

No, choose a twin needle size compatible with your machine and fabric thickness, typically between 2.5mm to 4.0mm for most projects.

Can double lock stitch be used for decorative purposes?

Absolutely! It’s often used for topstitching and adding parallel stitch lines for both function and style.

Warp up

That’s how a double lock stitch sewing machine works.

Have you tried it? How does it turn out?

Leave a Reply